Table Of Content

The overall depth of a floor truss is typically determined by a building designer depending on the mechanical purposes of the floor truss. Floor trusses are a great way to conceal mechanical, electrical, and plumbing systems as their open web design creates a naturally accessible space for various trades to ”hide” their work. Floor trusses can also be designed with a chase for air ducts to run perpendicular to the truss layout. Overall depth is a critical factor in determining which air handling systems can be designed for use in a given space. Every truss requires at least two bearings, or points, to transfer its loads to. Typically, it is a 2x4 or 2x6 wood frame wall or panel in residential construction but can also be a light gauge steel wall or block wall in commercial or industrial applications.

Our engineered wood and steel trusses at a glance:

To run cables, plumbing, or vents, you will need to make cuts in the I-joists. These include Open Web Floor Trusses, I-Joists, Solid Lumber Joists, and LVL Joists (Laminated Veneer Lumber). And since floor trusses improve structure efficiency and span greater distances, less material is used compared to other types of floor support. Versatile depths allow floor systems to incorporate sunken floor areas into the system. Walls can be framed at a standard height, and steps in the floor system can be created by the depths of the floor trusses, saving the framer time and the builder money.

Bottom Chord Bearing Floor Trusses

Webs requiring CLRs will be denoted on the Truss Design Drawing with a rectangle with an “X” through it or a rectangle fully blackened on the web. CLRs attached to similar adjacent trusses are required to have a diagonal brace to transfer the forces from the CLR into a lateral force resisting system such as the roof or ceiling sheathing. Another alternative to field applied restraints are factory installed stacked webs and proprietary metal reinforcements that have been specially designed for this purpose. When oriented on the flat face of the board, webs will be cut with bevels on each end to create more surface area at the joint for a better fit. In some instances, square cut floor webs can be used but result in larger plates at the joint. Typical floor joists will not span the exact distances compared to floor trusses.

84 Lumber opens newest truss plant in Richmond, Virginia - LBM Journal

84 Lumber opens newest truss plant in Richmond, Virginia.

Posted: Fri, 19 Feb 2021 08:00:00 GMT [source]

How to Build a Wood Floor Truss

Once again, it is important to have the design team help review the repairs to help identify any additional issues related to the repair. The repairs could impact other structural elements, plans for ductwork, or lighting plans. Anyone wishing to order or request a quote for trusses will need to know the span. In more complicated buildings, it will be taken off the construction documents and likely determined by a truss design and/or layout software specific to the component manufacturing industry.

HVAC

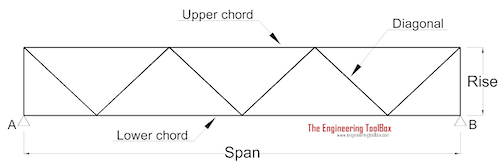

Raised Floor Living, in conjunction with Southern Forest Products Association developed a table to help understand how trusses are built. Members that join the top and bottom chords to form the triangular patterns typical of trusses. See the resources below for more information on how to specify, install and brace floor trusses. After all the components have been put in place, the connector plates or steel gussets are placed on the joints.

Floor Cassettes are manufactured at the plant and dramatically decrease installation time. In the above picture, all the continuous lateral bracing and X bracing were built-in, reducing installation labor even more. I-Joists are a manufactured product mostly made from OSB web or plywood material top and bottom flanges.

Steel Floor Joists

An automated roller is moved over the truss to press the barbs into the wood, which attaches to the connector plates. The ability to steal large lumber joists is also reduced, making them less likely to be stolen in great numbers. If you were to look at the truss from the side view, you would see a series of “N’s” in a row. The joints are fastened with connector plates made from barbed heavy steel gauges. Floor trusses can also be classified according to the materials used to make them.

US LBM Expands in Atlanta with New Floor and Roof Truss Manufacturing Plant - Roofing Contractor

US LBM Expands in Atlanta with New Floor and Roof Truss Manufacturing Plant.

Posted: Thu, 05 May 2022 07:00:00 GMT [source]

Once that step is completed, the trusses are flipped over, the connector plates are tacked, and the roller goes over the top to press the barbs into the wood on that side. Generally speaking, the deeper the floor truss, the more expensive it will be. Of course, there are many variations of the floor truss, although virtually all are based on either the Pratt or Warren design. Superior end reaction capabilities eliminate the need for additional structural band-board, web stiffeners, squash blocks, or blocking panels.

X-Shaped School Creates Unique Framing Challenges

Still, since LVL Joists are made from veneer, they can be prone to warping, which can be inconvenient. TrimJoist® is the marriage of an open-web floor truss and a trimmable, wooden I-joist, bringing the best features of each to the relationship. As the name TrimJoist® indicates, our product can be trimmed on the construction site for a custom fit. Welcome to the truss analysis tool for quick and efficient truss calculations.

Every one of our trusses has been individually designed and that design is checked and approved by licensed engineers for structural adequacy. The spacing requirements decrease when the number of trusses per floor is increased. Floor trusses can span long distances without the need for central support. Floor trusses can span over long distances, making them ideal for large spans. These trusses are designed to match the height of existing floors and subfloors. There are three types of trusses, and they differ in terms of shape, components, arrangement, and accessibility.

Trusses are made up of a series of panels, or the horizontal distance between the centerlines of two consecutive panel points along the top or bottom chord. Panels are imperative to the triangulation of the truss that allows the transfer of forces through the truss members and ultimately to the bearings. Typically, trusses are connected to the bearing temporarily with nails and permanently with a metal connector designed for uplift and lateral load considerations.

Easily analyze a wide range of common truss styles – including Pratt, Howe, and Scissor trusses – and now, any custom truss. Whether you need to design a determinate or indeterminate truss, we offer free versatility like no other with the powerful and accurate software behind Efficalc. This tool is designed to both save you time and improve the reliability of your designs. The architectural vision provided by Hacker Architects created a unique-shaped building set together with complex angles. Wood was selected for its economical benefits, along with the desire for aesthetic appeal with exposed material.

In addition to the space allowed for mechanical and plumbing runs, floor trusses can reduce framing time, material waste and callbacks. Far greater than EWP and conventional framing, cantilevers can include built-in details such as dropped top chords for balcony decking. Open web floor trusses can support greater concentrated loads, carrying bearing walls and roof loads from above.

Floor trusses are floor framing materials that make your construction job or project much more manageable. They offer the required support while providing maximum structural efficiency. You can quickly install them and ensure that they will not shrink, and they leave a lot of space for plumbing and wiring, making the whole process uncomplicated. Whenever we enter someone’s home, the first thing we usually notice is the furniture or the decor. Most people don’t pay attention to the home structure—the key that holds everything together.

No comments:

Post a Comment